During the renovation of marble and limestone, we are often confronted with the technical terms of grinding, polishing and crystallization. What do these terms mean?

Grinding of marble

First of all, grinding means that the floor is « scratched » and « smoothed » by means of an abrasive element. A rotating machine equipped with diamond grains will scrape the stone to bring the intact layer to the surface. Grinding also allows to remove the edges between the tiles (edge grinding) but also to remove the stains and cracks on the surface.

Mechanical polishing of marble

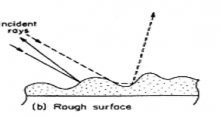

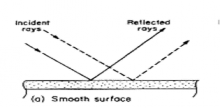

Mechanical polishing is a similar process but the used diamond grains are much finer than when grinding. Each step of polishing makes it possible to remove the scratches made during the preceding step, to obtain ultra fine scratches which are no longer visible to the naked eye. As the polishing continues, the roughness of the stone disappears and a mechanical gloss appears. The illustrations below show how the light is optimally reflected when the stone is perfectly smooth.

Crystallization

Finally, crystallization is a mechanical-chemical process that polishes the stone and reveals its colors. Crystallization however doesn’t remove scratches or stains and for great results is only applied after grinding.

Multiple types of crystallization can be used depending on the type of stone. The treatment “closes” the surface and improves mechanical resistance and ease of maintenance of the floor.

You can find more information about the characteristics of marble, its renovation, treatments, protection and possible finishes on the page Renovation of marble on the website of Emotion Pierres.